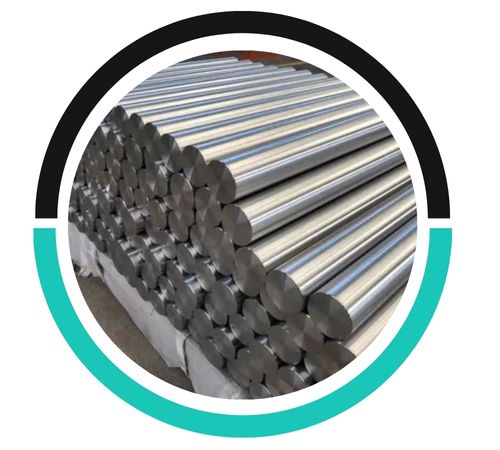

Neil Metals stands out as a dependable manufacturer and supplier of Alloy C263 Bar and Rod in Kolkata, India. They specialize in high-performance nickel-based superalloys tailored for critical industrial applications. Renowned for their commitment to quality and precision, Neil Metals ensures that their Alloy C263 products adhere to strict international standards, delivering exceptional strength, corrosion resistance, and stability at high temperatures. These bars and rods find extensive use in industries like aerospace, power generation, and gas turbines. With a strong emphasis on advanced manufacturing techniques and prompt delivery, Neil Metals has built a solid reputation as a trusted provider of Alloy C263 Bar and Rod solutions, both domestically and internationally.

The Alloy C263 Bar and Rod is primarily made of nickel, with key additions of cobalt (around 19–21%), chromium (19–21%), molybdenum (5.6–6.1%), titanium (1.9–2.4%), and iron (up to 0.7%). This unique blend results in a remarkable combination of high strength, oxidation resistance, and excellent fabrication properties. The alloy boasts a tensile strength of about 930 MPa and a yield strength of roughly 620 MPa at room temperature, along with impressive creep resistance up to 982°C. Its mechanical properties can be further enhanced through age hardening and solution annealing processes, making it ideal for challenging environments.

| Standards : | AMS 5872 |

| Size Range : | 0.015″ Thk up to 2″ Thk |

| Thickness : | Range from .008″ to .0125″ |

| Length : | 2m, 2.44m, 3m, or as required |

| Width : | 10-2500mm |

| Grade | Ni | Co | Cr | Mo | Ti | Fe | Mn | Al | Si | Cu | C | B | S |

| Nimonic 263 | 49 | 19-21 | 19-21 | 5.60-6.10 | 1.90-2.40 | 0.70 | 0.60 | 0.60 | 0.40 | 0.20 | 0.040 – 0.080 | 0.0050 | 0.0070 |

| Grade | Material Sheet | Temperature °C | Yield Strength 0.2 % (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness HV |

| Nimonic 263 | Nimonic 263 Round Bar Solution Treated (AMS 5872 / BS HR206) | RT | – | – | – | 22.5 max |

| Nimonic 263 Round Bar Heat Treated (AMS 5872 / BS HR206 | RT | 580 (typical) | 973 (typical) | 39 – | – | |

| Nimonic 263 Round Bar Heat Treated (AMS 5872 / BS HR206 | 780 | 403 (min) | 541 (min) | 9 | – |

| STANDARD | WERKSTOFF NR. | UNS |

| Nimonic 263 | 2.4650 | N07263 |

Yes, Alloy C263 bars are recyclable. As a high-performance alloy, it can be melted and reused for manufacturing new products, making it an environmentally friendly material in the long term.

Alloy C263 rods are available in various sizes ranging from 1/8" to 6" in diameter, with lengths typically up to 12 feet. Common finishes include hot-rolled, cold-drawn, and polished.

Yes, Alloy C263 (also known as Hastelloy C263) can be welded using appropriate techniques such as TIG or MIG welding, with careful control of heat to avoid carbide precipitation.

Alloy C263 Bar and Rod is particularly favored in high-temperature applications that demand superior strength and corrosion resistance. It is widely utilized in aerospace engine components, combustion chambers, afterburner parts, and turbine components, thanks to its stability and oxidation resistance at elevated temperatures. Additionally, this alloy is employed in gas turbines for industrial power generation, hot section parts, and even in nuclear applications where long-term thermal exposure is a critical factor. Its ease of fabrication and weldability also make it a great choice for components that require complex forming, machining, or joining processes.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved