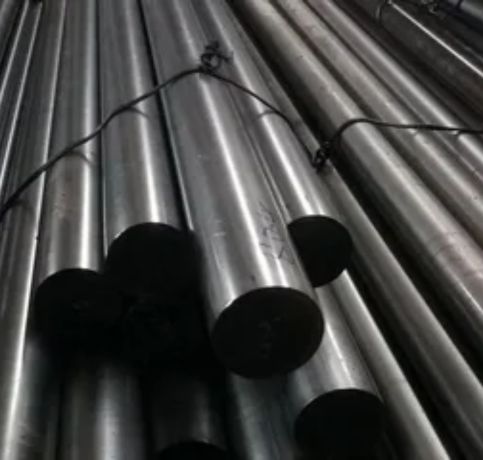

Neil Metals stands out as a leading manufacturer and supplier of 20MnCr5 Round Bars, proudly based in Kolkata, India. They specialize in delivering top-notch engineering steel products to various industries both locally and internationally. With a strong dedication to quality, Neil Metals provides precision-engineered 20MnCr5 round bars that adhere to international standards, making them perfect for demanding applications in the automotive, engineering, and machinery fields. The company is known for its unwavering commitment to consistent quality, precise dimensions, and timely deliveries, earning the trust of clients who seek high-performance alloy steel solutions. Thanks to their state-of-the-art production facilities and a skilled workforce, Neil Metals has become the go-to choice for 20MnCr5 round bar needs.

20MnCr5 Round Bars are a type of low-alloy case hardening steel, featuring around 0.17–0.22% carbon, 1.10–1.40% manganese, 0.15–0.35% chromium, along with trace amounts of phosphorus and sulfur. This alloy is renowned for its impressive wear resistance and strength after heat treatment, boasting a tensile strength ranging from 750 to 1000 MPa and a yield strength of about 500 MPa. With excellent hardenability, impact toughness, and fatigue strength, 20MnCr5 is particularly well-suited for carburized components. Its fine grain structure ensures reliable machinability, while its core toughness and surface hardness make it perfect for heavy-duty mechanical applications.

|

Element |

Content |

|---|---|

|

Carbon, C |

0.310 – 0.380 % |

|

Iron, Fe |

98.63 – 99.09 % |

|

Manganese, Mn |

0.60 – 0.90 % |

|

Phosphorous, P |

0.040 % |

|

Sulfur, S |

0.050 % |

|

Properties |

Metric |

Imperial |

|---|---|---|

|

Tensile strength, ultimate |

585 MPa |

84800 psi |

|

Tensile strength, yield |

370 MPa |

53700 psi |

|

Modulus of elasticity |

190-210 GPa |

29700-30458 ksi |

|

Bulk modulus (typical for steel) |

140 GPa |

20300 ksi |

|

Shear modulus (typical for steel) |

80 GPa |

11600 ksi |

|

Poissons ratio |

0.27-0.30 |

0.27-0.30 |

|

Elongation at break (in 50 mm) |

30% |

30% |

|

Reduction of area |

53% |

53% |

|

Hardness, Brinell |

183 |

183 |

|

Hardness, Knoop (converted from Brinell hardness) |

204 |

204 |

|

Hardness, Rockwell B (converted from Brinell hardness) |

89 |

89 |

|

Hardness, Vickers (converted from Brinell hardness) |

192 |

192 |

|

Machinability (based on AISI 1212 steel. as 100 machinability) |

65 |

65 |

| EN Name | EN Number | DIN | JIS | UNI | BS |

|---|---|---|---|---|---|

| C35 | 1.0501 | C35, CM35 | S35C | C35 | 970 070M36 |

Yes, 20MnCr5 Round Bars can be used for underground applications due to their high strength and durability.

Yes, 20MnCr5 Round Bars may require corrosion protection coatings for enhanced durability in harsh environments.

Choose 20MnCr5 Round Bars based on required strength, wear resistance, and application-specific environmental conditions.

Industries that require high surface hardness and robust core toughness widely utilize 20MnCr5 Round Bars. In the automotive sector, they are commonly used to manufacture gears, shafts, crankshafts, camshafts, and transmission parts. The alloy’s outstanding hardenability and wear resistance make it ideal for case-hardened components in machinery and equipment. Additionally, it finds applications in forging for creating heavy-duty fasteners, coupling components, and connecting rods. Moreover, 20MnCr5 is perfect for precision parts in the engineering industry, where durability and strength under dynamic loads are essential.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Neil Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Kolkata, India

Copyright 2024 Neil Metals. All rights reserved